HGV Brake Testing – As Per The DVSA

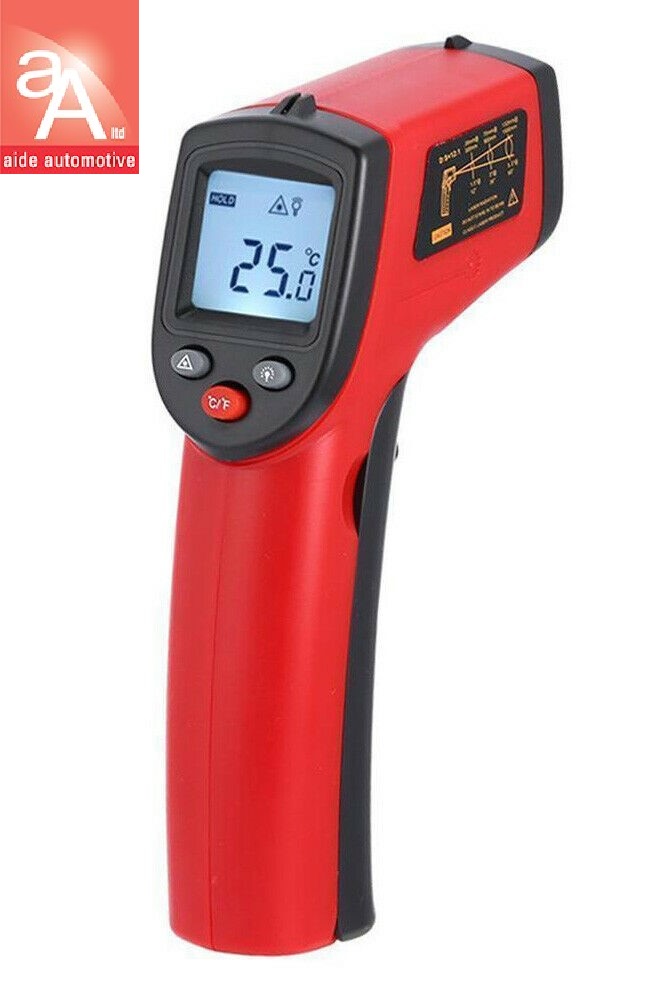

As you have purchased or are a user of a decelerometer, detailed below is the status of required testing of HGV’s as taken from the DVSA’s “Guide to maintaining roadworthiness” November 2018.

As within the industry we at aide automotive hear varied opinions of what is required when brake testing commercial vehicles, we have detailed the requirement as per the DVSA’s guidance.

No 1 – The current law could still be the fact that ONE annual MOT roller brake test (RBT) is the requirement.

No 2 – As the Health & Safety standards of the UK are of a high standard, duty of care laws could leave an operator open to the fact that high risk practices requires more testing.

No 3 – The DVSA’s “Guide To Maintaining Roadworthiness” should be used as the bench mark for all maintenance standards and be the minimum best practice.

So what does the Guide (For Brake Testing) say?

Safety inspection facilities

Facilities should include: • undercover accommodation for the largest vehicle in the fleet. This is required to ensure that safety checks can be conducted satisfactorily in all weathers (depending on fleet size the building may need room for more than one vehicle at a time) • tools and equipment appropriate to the size and nature of the fleet – access to brake test equipment (eg a roller brake tester, decelerometer)

As per the annual test, every safety inspection must assess the braking performance of the vehicle or trailer. It is STONGLY ADVISED that a calibrated roller brake tester (RBT) is used at each safety inspection to measure individual brake performance and overall braking efficiencies for the vehicle or trailer to the annual test standards. However, it is also acceptable to use an approved and calibrated decelerometer to measure overall brake efficiency values for vehicles without trailers.

Brake testing should be undertaken with the vehicle or trailer in a laden condition in order to achieve the most meaningful results; however, due to basic design limitations or restriction caused by the type of cargo normally carried, this is sometimes not possible

A printout of the brake efficiency test from either the RBT or decelerometer should be attached to the safety inspection record. If the brake test equipment cannot produce a printout, efficiency results must be recorded by the inspector on the safety inspection report. To help operators arrange a brake performance assessment with safety inspections, it is acceptable for a satisfactory brake performance assessment to be carried out within the same week of the planned safety inspection. Brake efficiency testing can be carried out by either an approved RBT or decelerometer test.

The conclusion! An O Licence operator should carry out a brake test on every inspection (to meet the DVSA guidance as above, although further detailed text does state “it is therefore normally expected that the vehicle or trailer should complete at least three successful brake efficiency tests spread throughout the year in addition to the annual MOT test), this can be achieved using an RBT or Decelerometer, the test should be printed out and attached to the safety inspection sheet. With regard to decelerometer tests, if the user decided to carry out the test laden, he/she should write on the printout as so: Laden / Un Laden.

If you are unsure about any of the above text or details, please do not hesitate to contact aide automotive.

Purchasing a Bowmonk BrakeCheck could not be any easier, just click on Purchase A BrakeCheck to review prices and buy!

Brake Tester Using Brake Efficiency to Report On Truck Brakes