Brake performance testing should be a key part of your maintenance regime that needs to happen at every safety inspection.

And, if you find any braking performance problems while the vehicle or trailer is in use, you’ll need to get a measured brake efficiency test before you use the vehicle again.

For most of you, this is standard practice and shows that you’re committed to running your fleet compliantly and protecting other road users.

Tragic consequences

But unfortunately some licence holders don’t meet the minimum standards and the consequences can be devastating.

In 2015, DVSA examiners investigated a road traffic incident involving a 32-tonne tipper vehicle. Four people, including a four-year-old girl, were killed when the vehicle’s brakes failed on a steep hill.

Our investigation found the operator’s brake testing was far below the required standards. The company’s approach to brake testing was nowhere near thorough enough, and on 5 out of 13 safety inspection records, the brake test section had been left blank.

In the other records, the comments were too limited for anyone to understand what they meant.

Successful court convictions

Two individuals from the company were each convicted of four counts of manslaughter at Bristol Crown Court.

The company director was sentenced to 7 years and 6 months in prison and the mechanic was sentenced to 5 years and 3 months in prison.

The Traffic Commissioner revoked the company’s operator’s licence and both the company and its director were disqualified from holding or obtaining another operator’s licence for two years.

Even if nothing this catastrophic happens, our vehicle examiners will still take your vehicle off the road and can issue you with a fixed penalty if they find dangerous problems with your brakes. This could lead to an investigation and referral to the Traffic Commissioner.

Following best practice

You should carry out routine safety inspections of your vehicles on a regular basis. Annex 4 of the Guide to Maintaining Roadworthiness provides tips for you to work out how often a vehicle needs to be inspected.

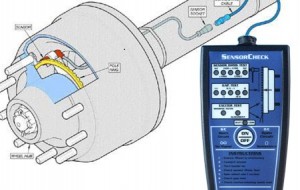

A braking test needs to form a part of each safety inspection. If possible, you should always brake test a vehicle or trailer laden. You should also use a calibrated roller brake tester (RBT) to measure:

? individual brake performance

? overall braking efficiency

You should undertake brake testing with the vehicle or trailer laden in order to get meaningful results. If this test shows the brakes aren’t working properly, then the vehicle or trailer isn’t roadworthy.

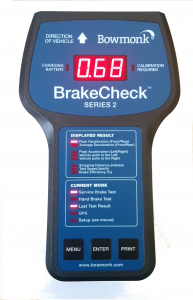

You could also use an approved and calibrated

decelerometer to measure overall brake efficiency if you’re testing vehicles without trailers.

And you should always try and obtain a printout of the brake test from either the RBT or

decelerometer and make sure it’s attached to the safety inspection record. If you can’t get a printout, the inspector should record the results on the safety inspection report instead.

If you can’t carry out a brake test during a safety inspection, the vehicle’s braking performance must be assessed using a road test.

This needs to be carried out under controlled and safe conditions. The safety inspection record should also say that the brake performance was assessed by a road test.

You can use an Electronic Braking Performance Monitoring System (EBPMS) to assess trailer braking performance using data collected while the vehicle is in use.

aide automotive market decelerometer brake testers for commercial vehicles, the

Bowmonk BrakeCheck is a known quality product for the UK’s truck, bus & coach market as well as around the world.

The latest addition to the

BrakeCheck range is the BrakeCheck GEO, with a built in GPS receiver this decelerometer will provide a GPS location to each brake test.